Twin Tower Air Heatless Desiccant Dryers consist of two towers containing a specialized material that absorbs the water vapor in the saturated compressed air stream. The amount of time that the saturated air remains in contact with the absorption material dictates the output air dew point (dryness) of the product.

When compressed air enters the dryer system through coalescing filters, 99.999% of oil, water and liquid contaminates are removed. The filtered air is then directed by the solid state controller to the on-line tower where saturated air and water vapor adhere to the desiccant in a process called “adsorption”.

While the on-line tower dries air, the off-line tower regenerates by purging the entrained moisture to atmosphere with a stream of dry air. The dry, clean air then exits the system through a dust removal filter into your plant distribution system.

SMC-IGS systems provide moisture free air down to a -40℃ or -100℉ pressure dew point.

No energy consumption in the heating process, but the consumption of compressed air will be bigger, as the pressure dew point of dry air is required to reach to -40℃, the consumption of feed air will be 20% during regeneration process, therefore, it is usually used for drying situations with smaller compressed air .

Remote contacts

• Pressure dew points to -100℉

• High humidity & failure to switch alarm

• ASME or GB coded vessels and moisture indicator

• High performance switching & check valves

• Control air, tower pressure gauges, safety valves

• Inlet and discharge filters

• Solid state controller and sensors

Features

• Cycle: T=10 (min)

• Power supply: AC 220V/50Hz

• Control: PLC

• Air consumption: ≤20%

• Oil content: ≤0.1ppm

• Pressure dew point: -40 ℃ (other)

• Pressure: 0.5~1.0Mpa

• Inlet temperature: ≤60℃

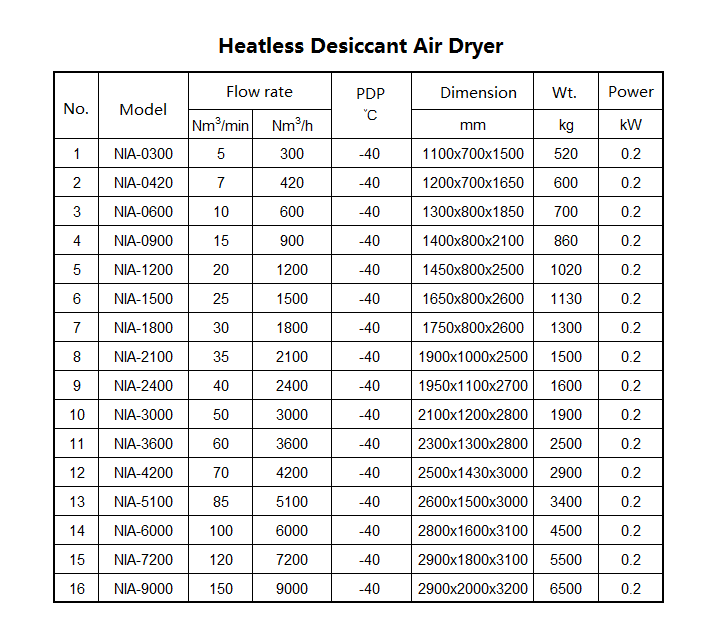

• Specification