How Membranes Work-Separation of Nitrogen from the Air

The membrane separation of gases is simple in concept. At the heart of technology are polymeric materials extruded into hollow-fiber membrane that allow for the rapid passage of some gases while minimizing the passage of others when applying a pressure gradient across the membrane.

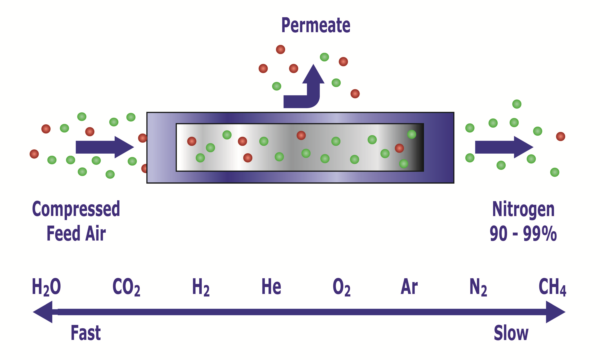

Figure 2 demonstrates the relative rates of common gases with the focus on the separation of oxygen and water vapor from compressed air to provide a high-purity nitrogen product stream. The IGS GENERON® polymer has the better properties for allowing O2 & H2O to permeate preferentially through the membrane walls relative to the N2 and inert Ar, resulting in the efficient air separation membrane performance and lower unit power consumption for nitrogen generation.

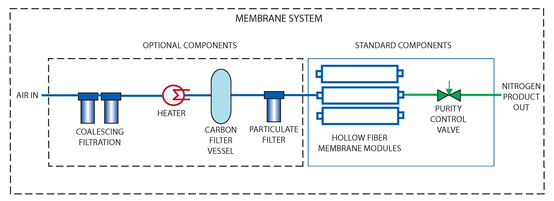

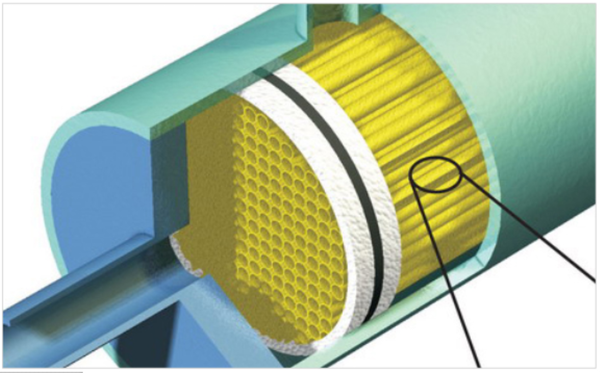

A IGS GENERON® membrane module may contain millions of single hollow-fibers. Compressed feed air is passed down the bores of the fibers at one end of the module with the enriched nitrogen gas exiting from the opposing end. Oxygen and water vapor are selectively removed and vented away from the feed air as it flows to the other end of the module. If the feed gas is supplied to the membranes with pressures greater than 500 PSIG, then a different flow scheme is used: In high-pressure applications, like CO2-Removal from natural gas, the membranes are supplied with the feed gas on the shell-side of the hollow-fibers and the permeate gas containing the “faster” gases are collected inside the bore of the membrane fibers. The IGS GENERON® membranes allow gas separation at pressures up to 1,200 PSIG and are maintaining a history of reliability unmatched in the industry!

IGS GENERON® modules the best available membrane materials with state-of-the-art fiber bundling and the optimum module fabrication methods to provide the very cost effective

solution for on-site nitrogen production... and we have over 60 patents to prove it!