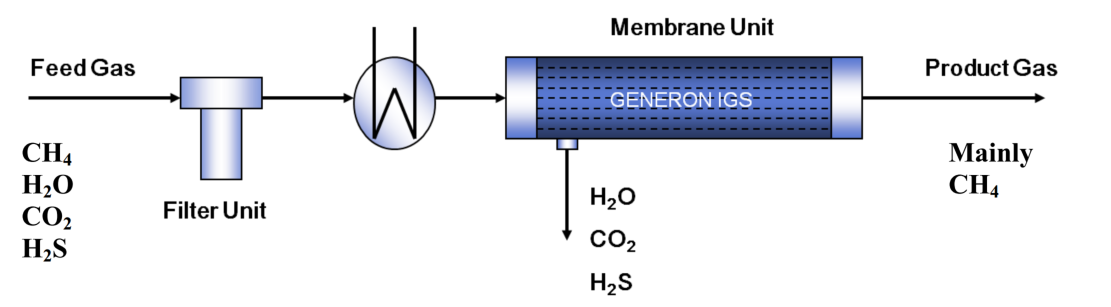

During anaerobic digestion or degradation in the absence of oxygen, organic material is decomposed by bacteria forming biogas, a mixture of CO2 and CH4 with trace amounts of H2S and H2O. The biogas can be used as vehicle fuel, in industrial processes or injected into the gas distribution grid, but first needs to be treated.

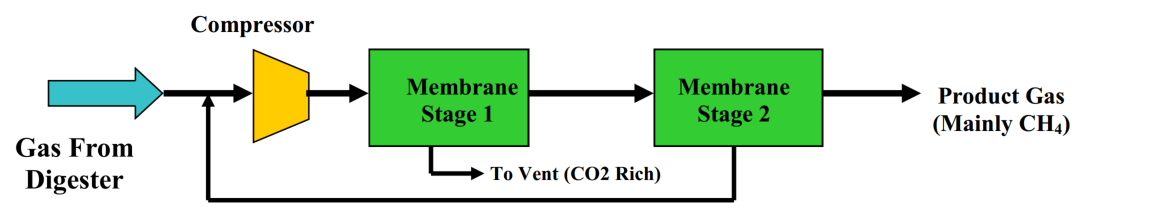

SMC ’s membrane systems are used to reduce the CO2 and improve the heating value of the gas. The systems also reduce the H2S and H2O content. SMC supplies customized biogas treatment systems, which also include the feed compression.SMC fabricates membrane modules and works directly with the client to provide the most cost effective solution.

The other alternatives for biogas treatment are absorption (water wash) or adsorption (PSA) systems. These systems are complex and have high capital, operating and installation cost as compared to membranes.

Performance

• Feed gas pressures up to 2,000psi (138bar)

• < 2% CO2 content in product

• > 98% recovery of hydrocarbon gas

• > 90% removal of CO2

• Flow rates: 10~540,000Nm³/h

Technical advantages

• Extensive Experience - Customer-designed skids

• State-of-the-art Membrane - High recoveries

• H2O Removal - No additional dehydration needed

• Simple Solution - No moving parts, less maintenance

• Remote Operation - Less attention required

• No Chemicals - Environmentally friendly

• Small Footprint - Easily meet footprint requirements