1. How does the PSA air separation process work?

2. How does the membrane air separation process work?

3. Is a PSA Nitrogen Generator better than a Membrane Nitrogen Generator?

4. Is it necessary to change the molecular sieve of PSA nitrogen and oxygen generators?

5. What are the specific benefits of the PSA nitrogen and oxygen generators from IGS SMC?

6. Why is the nitrogen purity expressed in residual oxygen content?

7. Why do I need an air dryer?

8. Can I use air compressors with an integrated air dryer?

9. Is desiccant dryer better than refrigeration drier?

10. What is the purpose of the gas receiver tank?

1. How does the PSA air separation process work?

See our PSA page under “Technology”.

2. How does the membrane air separation process work?

See our Membrane page under “Technology”.

3. Is a PSA Nitrogen Generator better than a Membrane Nitrogen Generator?

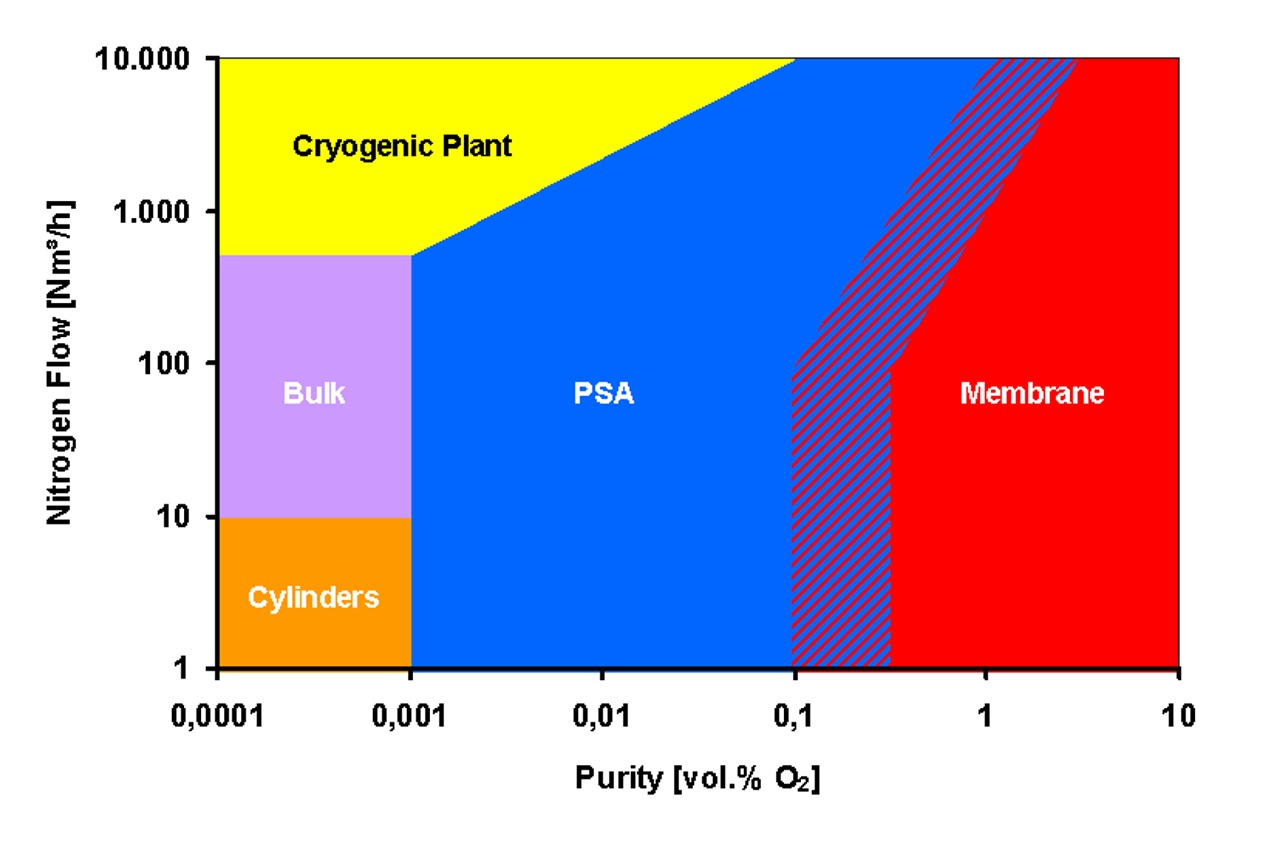

It is absolutely not for many nitrogen applications. Some suppliers make you believe that a PSA generator is the best solution, because they simply cannot offer you an efficient membrane technology. That’s the difference compared to IGS SMC. Besides our PSA technology, IGS SMC is also supplier of hollow fibre membrane systems for nitrogen production and air dehydration units. Our IGS GENERON® membrane modules set market standards in terms of efficiency and productivity. Having both technologies, we offer you the most suitable solution for your specific nitrogen application. Please see the following image of nitrogen supply below:

4. Is it necessary to change the molecular sieve of PSA nitrogen and oxygen generators?

Incorrect designed PSA generators from other manufacturers and/or the use of low-quality molecular sieves with insufficient strength do indeed need a regular renewal of their molecular sieve. Fortunately, the PSA generators from IGS SMC don’t require such major and very inconvenient overhauls.

As long as the feed air is of sufficient quality, the PSA generators from IGS SMC do not need any renewal of the molecular sieve during their entire lifetime. IGS SMC applied patents special to prevent fluidization to be happened, and we running tests before market introduction to assure low gas speeds through the molecular sieve beds and maximum durability. IGS SMC applies exclusively first-class quality molecular sieves for all its PSA nitrogen and oxygen generators.

5. What are the specific benefits of the PSA nitrogen and oxygen generators from IGS SMC?

Besides the general advantages of on-site gas generators, like an economical and just-in-time gas production without risk for gas price increases, the NITROSWING® and OXYSWING® PSA nitrogen and oxygen generators from IGS SMC offer you the following unique additional advantages:

Reliable: Small or large generators, all our products are simple operation, stable gas purity, minimum maintenance costs and a maximum system availability insure maximum customer satisfaction.

Flexible: The twin tower NITROSWING® and OXYSWING® PSA nitrogen and oxygen generators are the only truly flexible gas generators on the market.

Safe: The PSA towers of all our generators are thoroughly calculated and tested for fatigue cracking and have a mathematical infinite life time. No risks for your personnel, no need for renewal of your pressure vessel approval.

Efficient: The NITROSWING® and OXYSWING® PSA nitrogen and oxygen generators from IGS SMC produce more gas with less air than anybody else. And that you will notice in your monthly energy bill.

6. Why is the nitrogen purity expressed in residual oxygen content?

Non-cryogenic air separation processes by PSA and hollow fibre membranes do not produce pure nitrogen, but an inert gas, which mainly contains nitrogen, but includes also some other inert (noble) gases, like argon. Expressing the purity of this inert gas in amount of residual oxygen means simply saying how things really are.

If nitrogen produced from our PSA system, we say nitrogen purity 99.99%, and that means oxygen content is 0.01%. Actually, 99.99% included nitrogen around 98.85%, and argon will be 1.13%. Water content will be less than 20ppm.

7. Why do I need an air dryer?

An air dryer assures that air is supplied at the proper dew point for the ultimate generator performance. However, like the PSA generator and air compressor, the air dryer has to be selected for the high ambient temperature at the installation site in order to avoid that feed air with too high water content is getting to the molecular sieve. Below table show you saturated moisture content to various temperatures:

|

Temperature °C |

Saturated moisture content g/m3_air |

Temperature °C |

Saturated moisture content g/m3_air |

|

40 |

50.9 |

-12 |

1.81 |

|

38 |

46.00 |

-14 |

1.52 |

|

36 |

41.51 |

-16 |

1.27 |

|

34 |

37.4 |

-18 |

1.06 |

|

32 |

33.64 |

-20 |

0.888 |

|

30 |

30.30 |

-22 |

0.736 |

|

28 |

27.20 |

-24 |

0.590 |

|

26 |

24.30 |

-26 |

0.504 |

|

24 |

21.80 |

-28 |

0.414 |

|

22 |

19.40 |

-30 |

0.304 |

|

20 |

17.30 |

-32 |

0.277 |

|

18 |

15.36 |

-34 |

0.226 |

|

16 |

13.63 |

-36 |

0.184 |

|

14 |

12.05 |

-38 |

0.149 |

|

12 |

10.68 |

-40 |

0.120 |

|

10 |

9.35 |

-42 |

0.096 |

|

8 |

8.28 |

-44 |

0.077 |

|

6 |

7.28 |

-46 |

0.061 |

|

4 |

6.39 |

-48 |

0.049 |

|

2 |

5.60 |

-50 |

0.038 |

|

0 |

4.85 |

-52 |

0.030 |

|

-2 |

4.14 |

-54 |

0.024 |

|

-4 |

3.52 |

-56 |

0.018 |

|

-6 |

3.00 |

-58 |

0.014 |

|

-8 |

2.54 |

-60 |

0.011 |

|

-10 |

2.14 |

|

|

You can see in the table that moisture content at 40°C equal to almost 7 times at 6°C.

Normally, for PSA systems it is necessary to reduce the pressure dew point of compressed air to 3~8°C. To get such low pressure dew point, you do need a dryer.

8. Can I use air compressors with an integrated air dryer?

Only if the ambient air temperature at the installation site does not exceed 25°C / 77°F. Because the drying capacity of an air dryer will be strongly depends on the ambient temperature and the incoming feed air temperature. Integrated driers have an insufficient capacity at ambient temperatures above 25°C / 77°F and therefore the installation of a specifically sized separate air dryer will be required to guarantee the proper dew point for the ultimate generator performance.

Normally, we prefer to set air dryer after air compressor separately.

9. Is desiccant dryer better than refrigeration drier?

The compressed air from the air compressor normally has a temperature which is 10 to 15°C above ambient temperature. A correct sized refrigeration drier not only guarantees a sufficient dew point of the feed air to the gas generator, but also will cool the feed air. Feed air cooling has two important beneficial effects. But in desiccant dryer, moisture adsorption is an exothermic process. After adsorption drying of compressed air the temperature will rise. According to the moisture content difference, if entering compressed air temperature is 40°C, then it is possible after the drying of compressed air the temperature reach 45°C or higher. You know the higher temperature the lower efficiency for air separation process.

10. What is the purpose of the gas receiver tank?

The gas receiver tank allows the gas to be delivered to your application at a consistent flow rate and a consistent pressure. The size of the tank has little influence on the average discharge pressure of the produced nitrogen or oxygen, but smaller tanks increase the pressure fluctuations during the PSA cycles.

IGS SMC offers slightly larger gas receiver tanks than other manufacturers in order to guarantee a constant gas discharge pressure with no fluctuations.