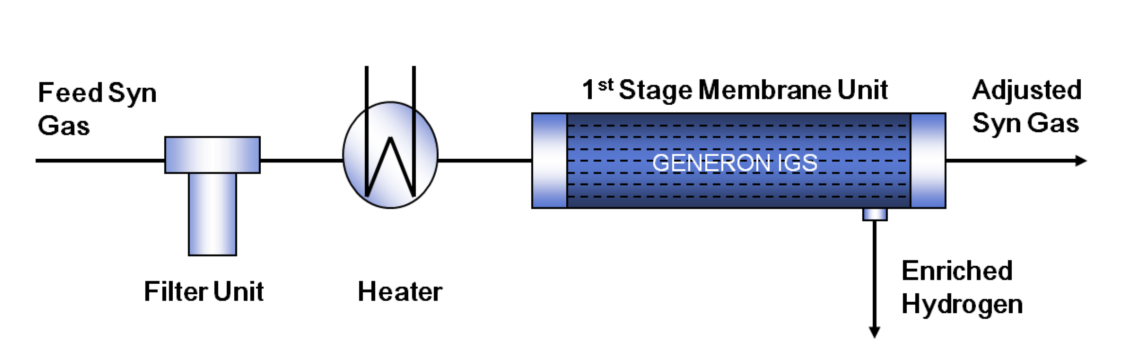

Syn gas (H2 + CO + others) is used to produce a variety of products. Each product requires a specific ratio of H2 to CO in the process feed gas to optimize production yields. Feed streams too rich in H2 can be adjusted by using membranes to selectively strip out the excess H2. The H2:CO ratio can be optimized effectively using SMC ‘s membrane systems

We can further boost the yields through system designs and blending schemes that take full advantage of membranes high selectively for H2. The vented off-gas of H2 can be at purities over 96%. Control of the process is very simple with arrays of membrane modules controlled with a single flow control valve. There are no moving parts to maintain and the flow is continuous and easily adjusted.

Depending on the feed composition one can purify CO with SMC membrane to over 95% with greater than 90% CO yields. If higher purities are required and/or if nitrogen is present in the CO rich feed gas, SMC ’s PSA (pressure swing adsorption) can be used to achieve purities up to 99.99%

Technical advantages

• Skid mounted process units are easy to connect and commission

• Built to your specifications and for your convenience

• Remote control operation

• Operation flexibility with automated part-load

• Engineering support from concept to completion

Performance

• Feed gas pressures up to 2,000psi (138bar)

• 90% to 99% CO + H2 recovery

• Lower maintenance cost (no switching valves) compared to H2-PSA

• CO+H2 purities to 95%

• Flow rates: 1~790Nm³/h

• Better economics than H2-PSA (lower price + faster deliveries, commissioning and start-up)

Applications

• H2:CO-ratio adjustment in syn gas

• Biomass-to-Liquid (BTL) biofuels production

• CO purification

• Gas-to-liquid (GTL) fuel production (Fisher Tropsch)

• Hydro-cracker purge gas

• FCC overhead gas