Helium is found in natural gas deposits. Helium has the low boiling point making it ideal to be used in cryogenics, particularly in the cooling of superconducting magnets, i.e MRI and NMR. It is also used in the process of growing crystals to make silicon wafers as well as other applications mentioned above. SMC ’s helium recovery membrane systems offer a good way to recover the helium efficiently and cost effectively from gas. SMC works directly with the client to provide the efficient and cost effective solution.

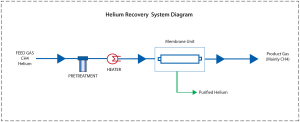

For helium recovering, the feed gas is first filtered to remove any particles and condensate. Helium gas permeates extremely “fast” through the membrane walls. The permeated gas is the helium rich product stream with purities in the upper 90% range. The “slower” permeating gases are collected in the non-permeate (“retentate”).

Technical advantages

• Extensive Experience - Custom designing

• Simple Solution - No moving parts, maintenance

• State of the Art Membrane - High recoveries

• No chemicals - Environmentally friendly

Performance

• Feed gas pressures up to 2,000psi (138bar)

• Helium purities to 99.9%

• > 98% recovery of Helium

• Flow rates: 10~540,000Nm³/h

Applications

• Circuit breakers

• Cryogenic

• Leak Detection

• Controlled atmospheres

• Electronics

• Welding and Fabrication

• Silicon Wafers

• Lift Gas

• Breathing mixtures (diving)