Sulfur hexafluoride, SF6, is used around the world as a dielectric medium for high-voltage circuit breakers, switchgear, and other electrical equipment. Additionally, it is used for the filling of insulated windows and for the casting of magnesium. SF6 is expensive and is also a powerful green house gas (20,000 times more potent than CO2). SMC membranes allow SF6 to be retained at high pressure (close to feed pressure) while permeating out the unwanted air.

SMC ’s SF6 Recovery systems help cut the SF6 emissions by > 90% with a projected payback time of less than a year (for most applications). The customized SF6 Recovery Systems® are manufactured in our ISO 9000 Certified facility in Chengdu, China while the membrane is fabricated in our Pittsburg, USA facility. SMC-IGS works directly with the client to provide the most efficient and cost effective solution.

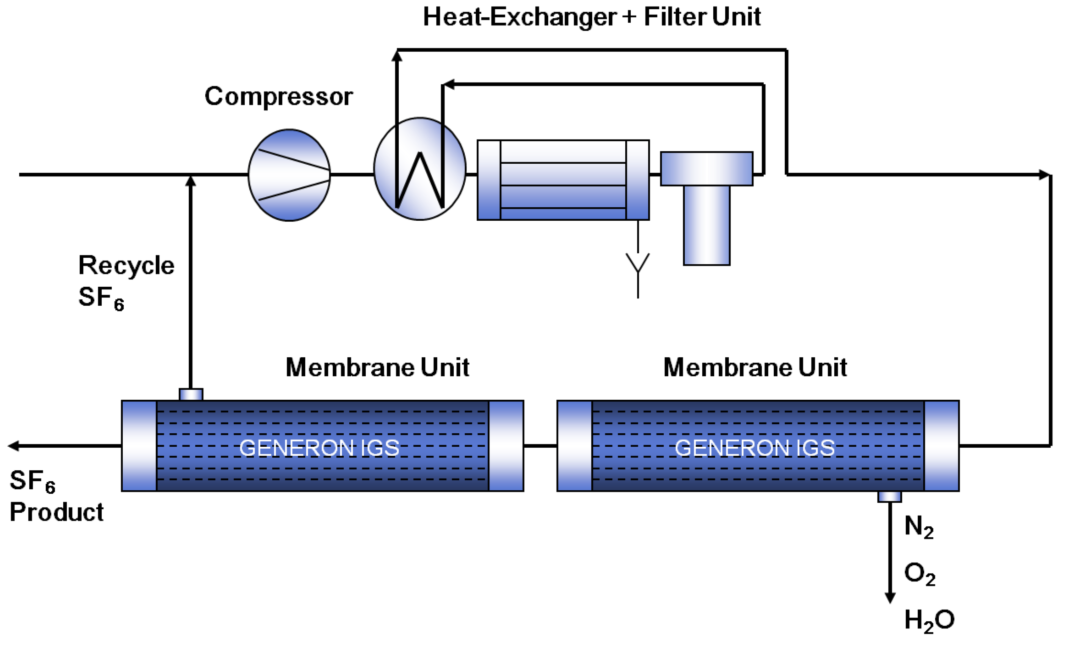

Feed gas is compressed and filtered to remove particles and condensate. A heating step provides an optimum operation temperature for the feed gas to enter the SMC membrane modules. SF6 gas permeates extremely “slow” through the membrane walls and remains at pressure. The “faster” permeating gases, e.g. N2, O2, H2O, are removed with the permeate.

Technical advantages

• Extensive Experience - Custom designing

• Simple Solution - No moving parts, maintenance

• State of the Art Membrane - High recoveries

• No chemicals - Environmentally friendly

Performance

• Feed gas pressures up to 2,000psi (138bar)

• <5 vol % SF6 in feed

• > 90% recovery of SF6

• Flow rates: 1~1,500Nm³/h

Applications

• Transformer manufacturing

• Window thermal insulation

• Circuit breakers

• Magnesium casting

• Electrical switch-gear

• Sports Shoes