CO2 is commonly found in natural gas. In order to meet pipeline specifications or other application specific requirements, the CO2 has to be removed. In addition, there may also be H2S and H2O present that needs to be removed. Membranes have been widely used for CO2 removal applications and come with the added benefit of removing H2S and H2O as well.

SMC-IGS supplies customized CO2 removal systems. IGS fabricates its own membrane modules and works directly with the client to provide the most cost effective solution.

Technical advantages

• Extensive Experience - Custom Designed Skids

• State-of-the-art Membrane - High Recoveries

• H2O Removal - No additional dehydration needed

• Simple Solution - No moving parts, minimal maintenance

• Remote Operation - Minimal attention required

• No Chemicals - Environmentally friendly

• Small Footprint - Easily meet footprint requirements

Applications

• Pipeline gas applications

• Biogas or digester gas

• Enhanced oil recovery (EOR)

• CO2 capture from stack / flue gas

• Fuel gas conditioning

• Syn gas from steam-reforming of natural or biogas

• Methanol cracking

• H2-PSA purge gas

• Methanol Production

• Gasification plants (IGCC)

Bulk removal upstream of an amine plant

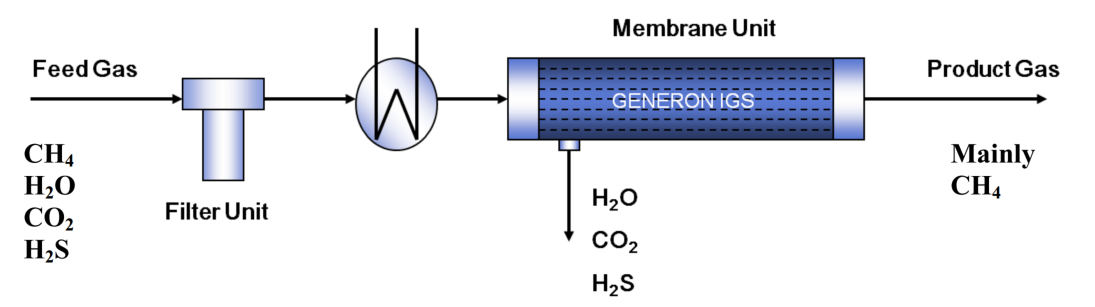

SMC CO2 removal membrane system the feed gas is first filtered to remove any particles and liquid condensate. The gas then enters the membrane modules. The CO2 as well as any H2S and H2O permeate preferably through the membrane. The non-permeated gas, mainly CH4, remains at pressure and is the product gas.

Performance

• Feed gas pressures up to 2,000psi (138bar)

• > 60 vol% CO2 in feed

• < 2% CO2 content in product

• > 98% recovery of hydrocarbon gas

• > 90% removal of CO2

• Flow rates: 20~500,000Nm³/h